On this particular car night with my buddies, we went out to investigate a loud hollow noise coming out of my one buddies Chevy ’02 Suburban. He sent a video to the guys of our group of the noise coming from his Suburban and from what we all heard we all thought the noise was a upper engine noise. Thinking it may be a head noise like it sucked a Valve or a loose Rocker-Arm.

Now the noise sounds like it went through the exhaust because it was a hollow noise ( a loud echoing noise) and so going by this noise is what we were guessing just by the video he sent to all of us. First chance we had to be around the truck in person was after a bunch of us got together one Saturday. We were there in person to hear it. And there is no way this noise was coming from the upper part of the engine.

We diagnosed it as possibly the starter or inspection cover hitting the flex plate but it was so late in the day we decided to do it our next chance on our next “car night” to dig into it.

We finally got our chance to tear into it. My buddy had already started taking off the exhaust pipes and we had to also remove the front driveshaft to the front axel for us to finally remove the inspection cover. Once the shaft was out of the way, we got the inspection cover off with a lot of metal shavings from the damage caused to the inspection plate and we finally saw the culprit that had caused all the noise and all the damage to the poor inspection cover.

We got extra lucky here that the torque converter wasn’t damaged here also.

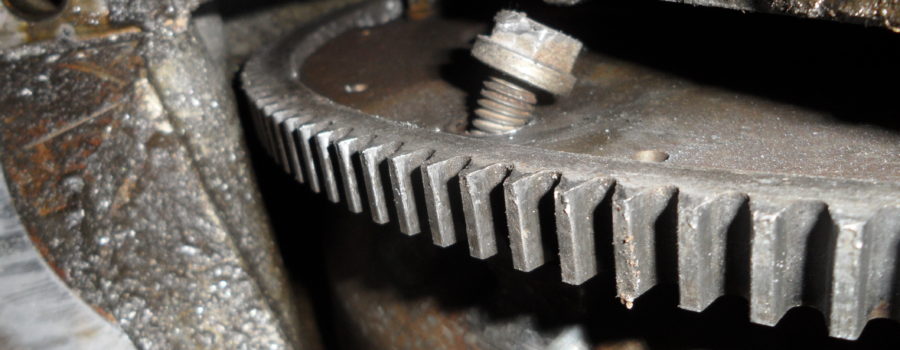

Metal Shavings from all the damage that darn bolt took away.

WOW!!! What a curve.

One bolt has worked its way out of the flexplate that bolts itself to the torque converter. Now the fun begins! We turn this engine with a pry bar because the bolt was at the top when we pulled the inspection cover off. Lucky for us was able to unscrew the bolt by hand and this bolt was REALLY messed up after all the damage it has caused from being loose.

WOW! Look at all that damage from this little bolt.

The only downside is, the welded nut that it screws into on the torque converter had taken some damage also from the bolt getting hit, it bent it out of alignment but not enough that we could not put a new bolt back in. So that’s what my buddy did. He bought a new bolt from the dealership and he coated it with red loc-tite and also torquing it down with a torque wrench making sure this bugger will not come out again in the future!

Another look at this little trouble making bolt!

After doing this bolt he continued with the other bolts to be sure they were all tight also. I suggested to him to clean out the bell housing of all the metal particles from all the damage done by the bolt and the inspection cover so it may not cause damage to the rear main seal. Once we had that all done we were ready to bolt the inspection cover up and put the shaft back on and bolt up the exhaust pipe and she’s ready to go back to work!