I initially wanted to replace this wire harness with a new one, but I couldn’t find one actually made on American soil. So I took it on myself to find all the supplies required to rebuild this harness from the fuse box out to both signal housings. Now finding the exact terminals in the connection housings for this old of a truck, I didn’t think it would be so hard’ I did find an assortment pack but it only came with two terminals for my little pickup. I required more for this project. So I went to look up various supply catalogs for my little truck without any luck. So I resorted to looking up eBay to find, if possible, a seller may have these male end terminals that I needed. So with taking quite some time, and the right description typed in, I FINALLY found not only the male terminals, but I also found the female end terminals. The price was right and the shipping was FREE! Now all I had to do is find the right gauge of wire, then also find the correct color of each wire to correspond with my trucks original wires which were 10 gauge. Once I had everything, all I had to do was to get the light socket pig tails. They had to match to fit my old truck, which were for the old incandescent light bulb number: 1157.

Now the fun begins! I start pulling terminals out of the original plug connector from the fuse box, making sure to cut the new wires to the exact length or a little extra (it never hurts to have extra length). I started with connecting wires to my pigtails sockets, then I ran down to my local auto part store to get me some more electrical tape, then went back at it. Now working on my harness, I did not have my clips to clip this harness back on the under side of my hood, so I tried to reuse my old ones for which did not work. LOL. But at least it helped me mark where one day when I get the new ones, where sitting.

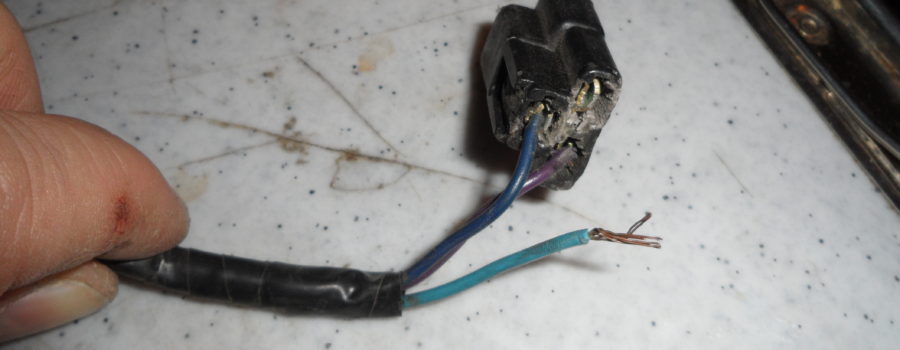

So after the lights are done, I went to my connection that plugs into my fuse box, and I carefully use a tiny straight fit screwdriver so I can loosen the terminals to pull them out while trying to save the connection housing. Now looking at my connection housing I did a damn good job at saving it! So it can stay in this truck as it is, an original part. Now once trying to pull these out I also used a pair of needle nosed pliers, BUT, be gentle if the screwdriver didn’t release the finger holding it, you may have to wiggle the terminal side to side with your pliers to help it out of there, but be gentle, do NOT break the housing (whatever you do, do NOT stick this housing in a vice or hold onto it with another pair of pliers).

Now, in the pictures you’ll see I got my new clips for my harness, so I was taking off the old ones and putting in my new ones, as you can tell, the old ones are pretty brittle. So don’t force them, they won’t be used again but I did not want to ruin all my work on building my harness in the process at taking these off again. As you can see my new ones look great! I am so excited to finally have this project of rebuilding this harness completed and it will no longer hang down from the underside of my hood and my turn signals, I know will work a heck of a lot better! This is my second wire harness rebuild that I’ve done on this truck and I’m finally satisfied!