My wife’s Lil’ Olds brakes needed work! They were making a noise like grinding steel on steel. We first thought it was the rear because it was a hollow sound. So we ordered rear rotors and brake pads then I tore into it. I practice safety first, I block the front wheel with a block of wood. Break the lug nuts before getting the wheel up off the ground. Then finish getting the weight off the tire, then brace the car with the jack stand. Then after I inspected them, they weren’t bad at all! It’s the front ones!

Well, now I get back to the parts store again, yay!!! Now we have everything, time for fun. Ok, I have all my tools, I think.

Metric sockets – 3/8 & 1/4 drives

Ratchets – 3/8 & 1/4 drives

Extensions – 3/8 & 1//4 drives

8 inch C-clamp

Pry bar

Red Thread locker

Disc brake lube

Anti-seize lubricant

Gloves

A lug wrench or X-wrench

Floor Jack

Jack Stand

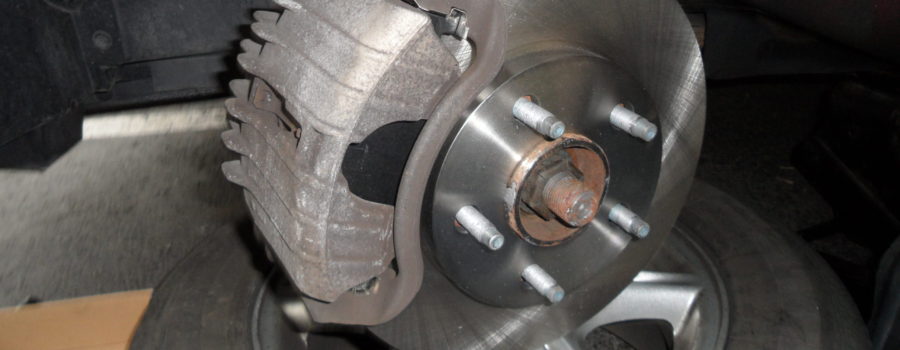

Now, I am ready to block the rear tires and set the emergency brakes, jack-up the front end 1 at a time. because I’m working on the flat blacktop. (Loosen the lugs while weight is still on them with the lug wrench.) Then sit the car on the body jack, safely. Grab the 3/8 drive ratchet with 12 mm bolts size socket, I find the studs that hold these bolts screw into, they will turn on me, so grab a 15 mm open-ended wrench to hold it to remove the bolt. Now I can remove the whole thing but I had to watch how the hose was turning, not to bend it too far.

Then remove the caliper frame, those bolts are 13 mm, simple but tight. Once you have it off you can remove the rotor, then replace everything in reverse – New rotor first, caliber frame next. Now when putting in the bolts for this; you need to squeeze some red thread locker on these bolts. Not a lot, just an even line to both bolts then install them. Then grab an old brake pad and the c-clamp and use them to compress the piston into the caliber. Then install the new pads into the brake caliber frame with shims. The caliber is next. Grease the studs that the caliber bolts screw into – they come out! (With a little help) They have a little boot on them for protection from dirt and they are needing grease whenever you are doing brakes. Pull out, then grease, then snap boot over hard plastic “like” lock washer. You see in my pictures how it will look. Make sure it clicks over then you can continue with the reinstall of the caliber and then your tire. But before your lugs are put on, use some anti-seize on ( just a little) these lugs for safety, it protects from rust and it won’t lock the lugs on in the future.