What this started out as originally, was doing work on my electrical system for a charging problem I was having. Here my horn relay was under the washer bottle and bracket, so I thought to remove it to get better access to the relay. So I noticed that this bracket was in pretty “ugly” looking condition. So, thinking it may be good for me and my truck to clean this up a little and see what it may look like. IF I could salvage it. Also, saving money by stripping it myself and painting it.

washer fluid bottle bracket

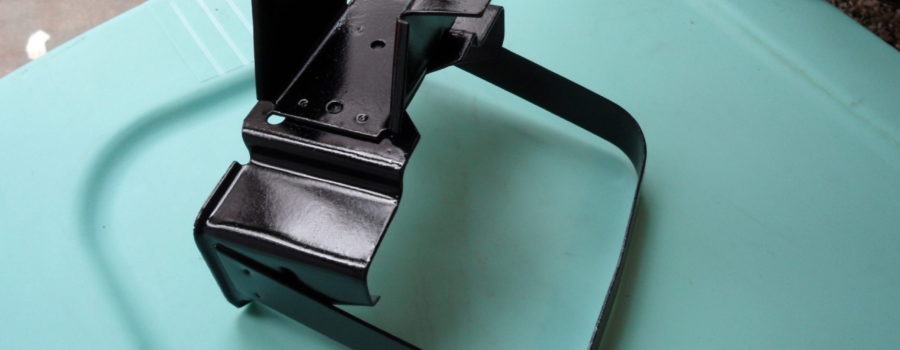

Unrestored bracket

Over 51 Years old here

Aged part

Aged part

Before stripping process

Well, as usual, if you have read any of my other posts, I started with a wire wheel for this project. Being this was going to be hard to hold onto, I put this into my bench vice. Now you must remember this is metal it is not paper thin or very thick. So handle with care. Don’t push hard when stripping this, just use the weight of the wheel as the pressure, unless you use a courser head wire wheel. They do very well by themselves. All it takes is a little patience, cause this part has some tricky corners and edges. You will have to watch out for your drill because it will jump on you. Always practice safety when around power tools of any kind.

The underside of our washer bracket

washer bottle stripped clean

It was hard to get to the hard-to-reach areas that are where my sandpaper comes in.

Stripped to clean metal ready for the primer coat

Having great patience will pay off here. Because it’s a labor of love!

Love seeing the results here.

List of what you need

safety glasses

some type of protective gloves

medium grade wire wheel made for drill attachable

fine grade wire wheel

3/8 drive electric drill

80 grit metal use sandpaper

bucket of water big enough for the part to rinse it

shop towels or paper towels

GM flat black O.E.M. engine paint.

The finished product

Like new again gives me great joy to return everything the favor to my truck for ALL he has done for me over 20+yrs

The washer bottle bracket is perfect.

The washer bottle looking like new again gives me such great joy that I could return everything this truck has done for me over the last 20+yrs.